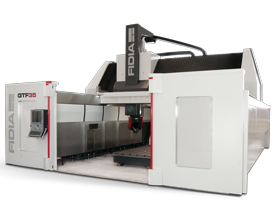

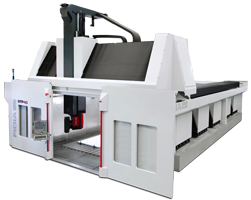

GTF/R

GTF/R Made of stiff epoxy concrete columns to allow the best vibration dampening effect, these versions of GTF family have the greatest level of modularity, thanks also to the automatic heads changing system. Starting from the smallest 2+2 columns configuration, the same design can be extended to any X axis length just by adding columns. GTF/R Brochure GTF IT 0 file(s) 4.58 MB No file attached GTF EN 0 file(s) 4.58 MB No file attached GTF DE 0 file(s) 4.59 MB No file attached GTF PT 0 file(s) 2.95 MB No file attached GTF Series' brochure GTF IT 0 file(s) 4.58 MB No file