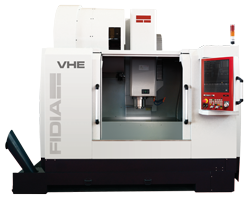

XPOWER

XPOWER Fidia XPOWER series digital drives have been designed to solve all axis and spindle movement problems. Ideal for mounting on a wide range of machine tools, the drives are particularly suited to milling machines and machining centres. Main characteristics: FULL DIGITAL drives with DSP 32 bit processing 90 Mbit/s proprietary FFB bus programmable switching frequency to optimize the thermal performance of the motor: up to 8 kHz for the axes, up to 16 kHz for the electrospindle encorder interface or ENDAT for motor position feedback optical scale axis interface or ENDAT PTC input for measuring the motor temperature parameter setting software integrated in