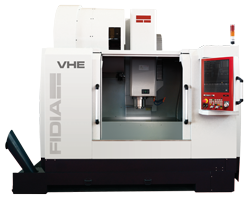

VSE

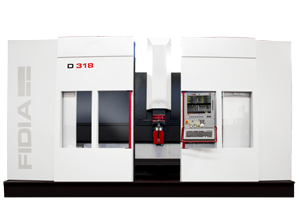

VSE Fast and accurate, the high speed vertical 3 axis machining centers, are characterized by a robust cast iron structure. The wide range of machines starts from versionVSE1066(1,020x610x610) mm. The use of both motor-spindles with high torque, and electrospindles, make the VSE an extremely versatile machining center. Owing to their rigidity, stability and dynamic characteristics, VSE machining centres offer high speed roughing out and finishing. VHE/VSE brochure VHE/VSE ITA 0 file(s) 2.41 MB No file attached VHE/VSE ENG 0 file(s) 2.41 MB No file attached Catalog E-Line E-Line ENG 0 file(s) 933.03 KB No file attached E-Line ESP 0 file(s) 932.91 KB No file