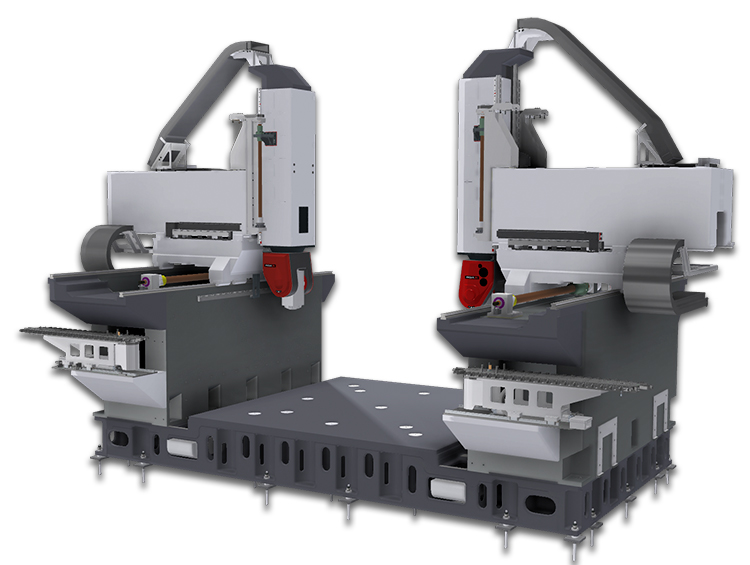

2-K2010/M_Milling_system

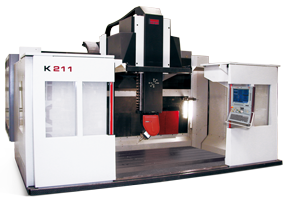

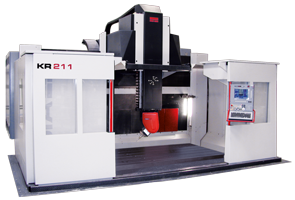

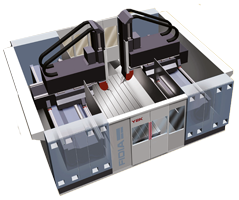

Milling System 2-K2010/M FIDIA’s experience as the sole supplier of an overall solution has made possible this particular configuration: two standard systems, with a shared cast iron table, doubling productivity with respect to other gantry systems having a similar work volume. This Boxer configuration lends itself to optimum integration with FMS. Each K2010 module draws on the features and basic structure of the K Range. K Range' brochure Serie K ITA 0 file(s) 2.40 MB No file attached Serie K ENG 0 file(s) 2.39 MB No file attached Serie K POR 0 file(s) 3.22 MB No file attached Serie K DEU 0 file(s) 2.88